250GT MTII SWB Chassis

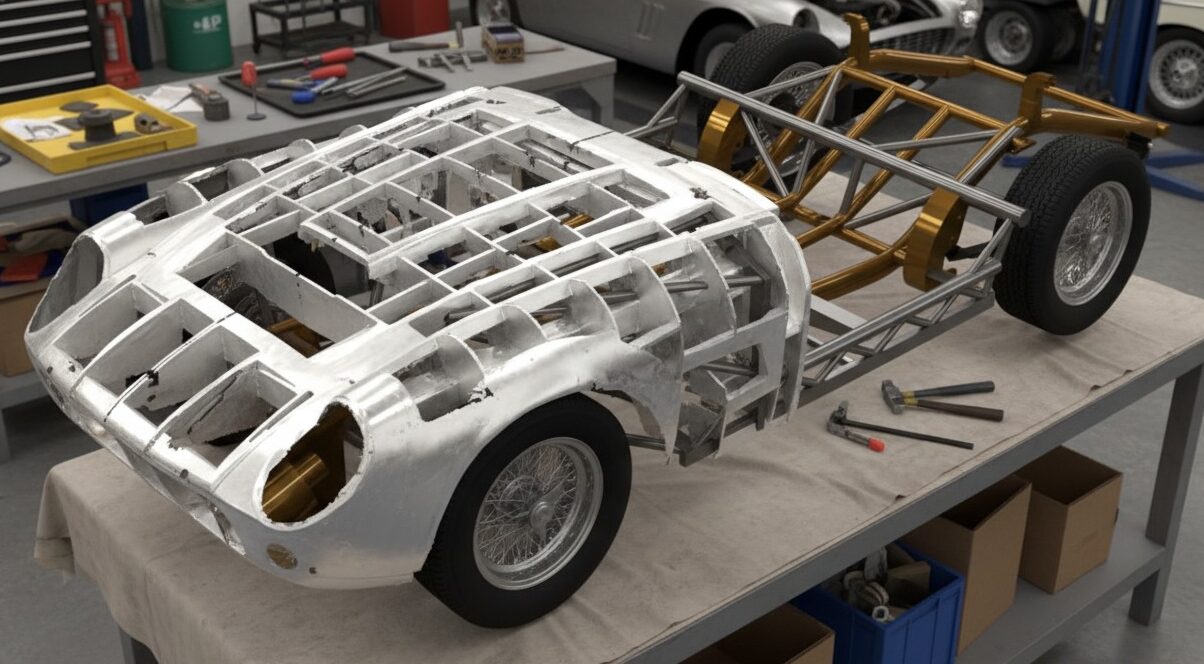

This project represents my interpretation of the iconic 250GT California SWB chassis. While the original frames were hand-built by skilled craftsman (Carrozzieri) using whatever tubing was available at the time, today’s fabricators can take advantage of modern materials, precision cutting, and repeatable jig work. The goal here is to honor the intent of the original design while making construction practical and achievable with readily available components.

My Interpretation of the 250GT California SWB Chassis

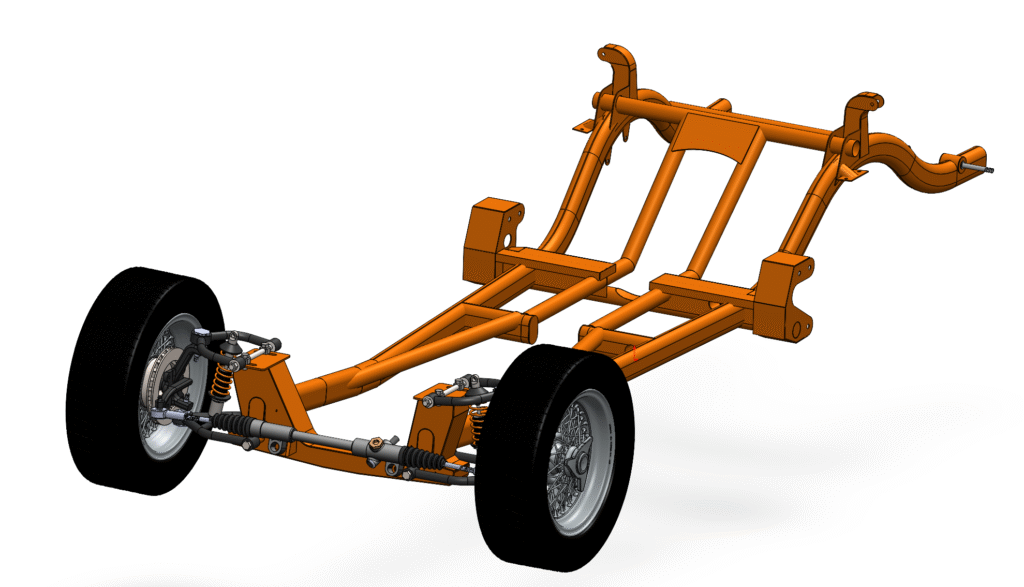

The main structural members are specified in 3.0 inch semi-oval tubing, which closely replicates the dimensions and stiffness characteristics of the historic chassis sections. This tubing is widely available in modern alloys, making it both cost-effective and consistent in quality compared to the mixed stock used in the post-war era. By standardizing the tube size, the entire backbone of the frame can be fabricated with predictable strength and a high degree of accuracy.

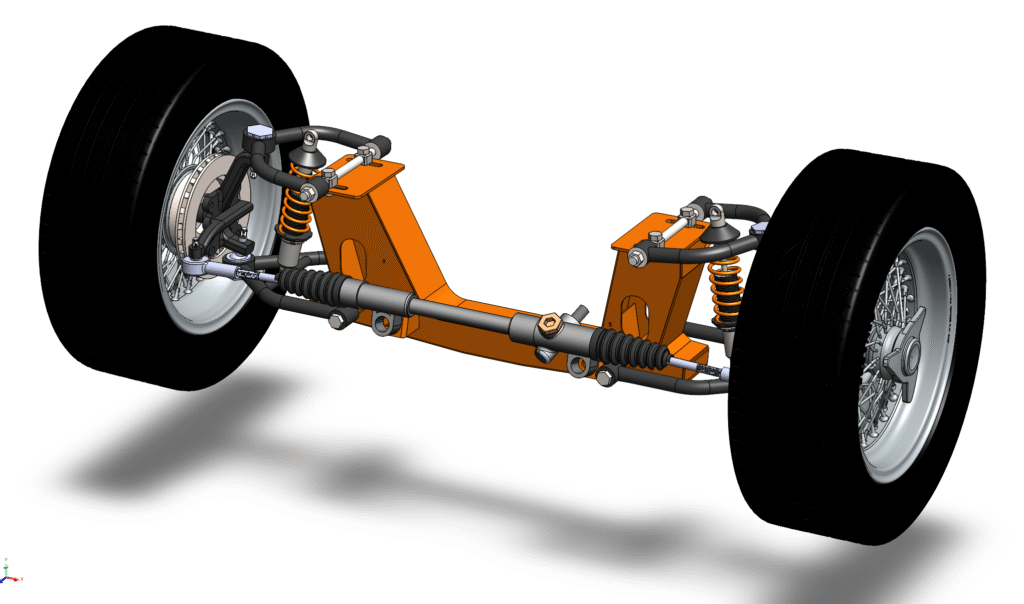

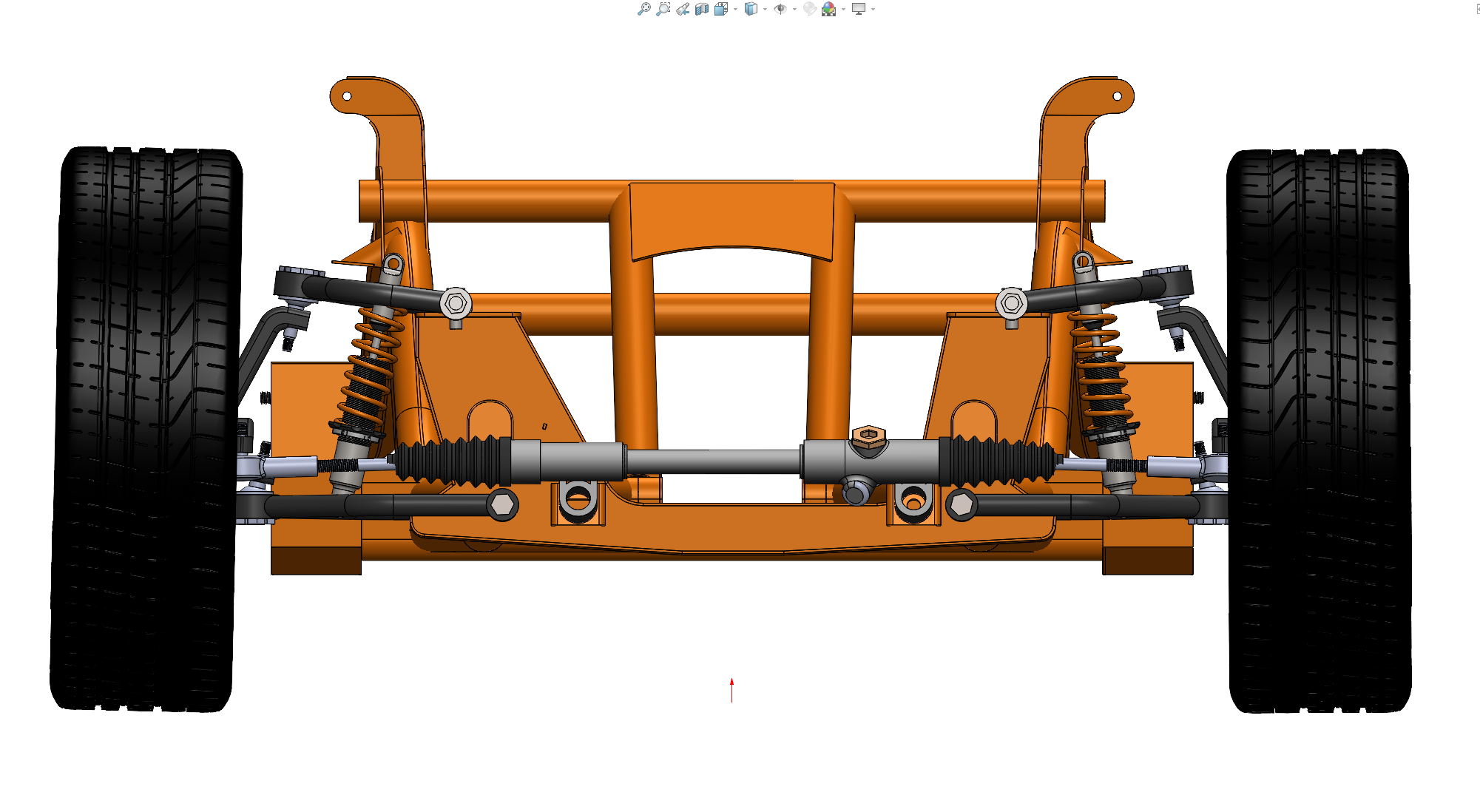

The front traversa (cross structure at the nose of the chassis) can be manufactured as a matching assembly to help aline the main oval tubes. Careful alignment of the traversa ensures proper suspension geometry, steering rack placement, and engine bay clearance. With the right fixtures in place, the frame and traversa can be jigged together quickly, producing a structure that is true to the proportions of the original while benefiting from my improvements while adhering to modern tolerances.

To complete the structure, the central cross member is designed from 1/8 inch steel plate. This plate can be laser-cut or plasma-cut directly from CAD files, ensuring each piece is dimensionally identical. Positioning tabs and slots are incorporated into the plate design, which makes assembly far more straightforward: the pieces “lock” into their intended location before welding. This eliminates guesswork, reduces clamping time, and guarantees a square frame once fabrication is complete.

The result is a chassis design that blends tradition and technology. It respects the spirit of the original 250GT California SWB but embraces the advantages of modern suspension systems and fabrication. Readily available tubing, digital cutting technology, and smart use of alignment tabs make this frame not only possible for skilled builders today but also practical to help this project in recreating a historically significant structure with contemporary precision.

While this stage remains a concept design, every dimension has been laid out to remain true to the original 2400 mm short wheelbase frame. That compatibility ensures that any builder wishing to improve a 250GT chassis could use this interpretation without straying from the geometry that made the SWB so famous for its balance and agility. Even as a paper exercise, the design work highlights how traditional craftsmanship and modern fabrication techniques can coexist in a way that honors the past while looking toward the future.

The idea of constructing such a frame makes for an exciting prospect. It would not only be a rewarding engineering challenge but also a chance to physically experience the qualities that defined the great cars of the early 1960s. From the oval tubing of the main rails to the precision-cut cross members, each element invites the builder to engage with the same principles that guided artisans in Modena decades ago.

The logical next step is to address the rear suspension. In keeping with the period-correct layout, the design will incorporate semi-elliptical leaf springs working in harmony with the solid rear axle. This arrangement, while simple by modern standards, offered durability, ease of adjustment, and predictable handling characteristics that suited both road use and endurance racing of the era. Exploring how to integrate this suspension system into the frame will provide the next chapter in developing a faithful yet practical interpretation of the SWB design.