Struttura Portante (Support Structure)

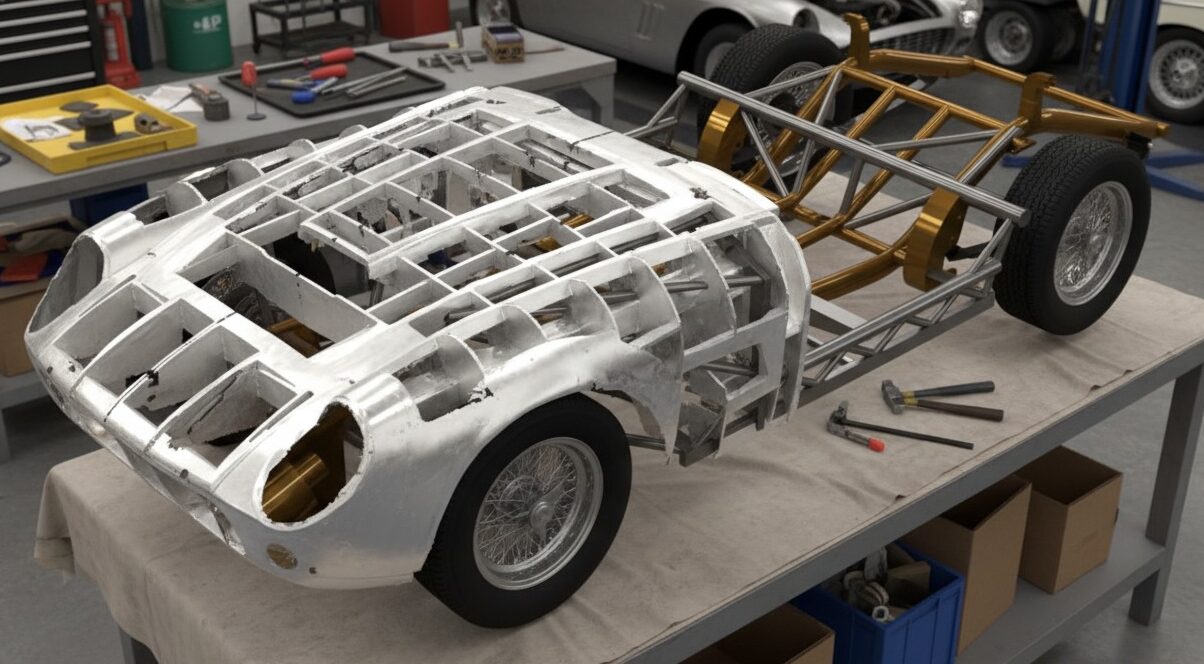

Once the telaio (steel chassis frame) of our DIY 250GT California is complete, the next step is providing a scocca portante (body support structure). This substructure is important because the thin aluminum body panels need a stable, rigid foundation to attach to. In period Ferraris, as in most Italian coachbuilt cars of the 1950s and 1960s, this was accomplished by welding a carefully designed steel framework onto the chassis. Over this framework, aluminum panels were hand-shaped and fitted with rivets, screws, or clamps.

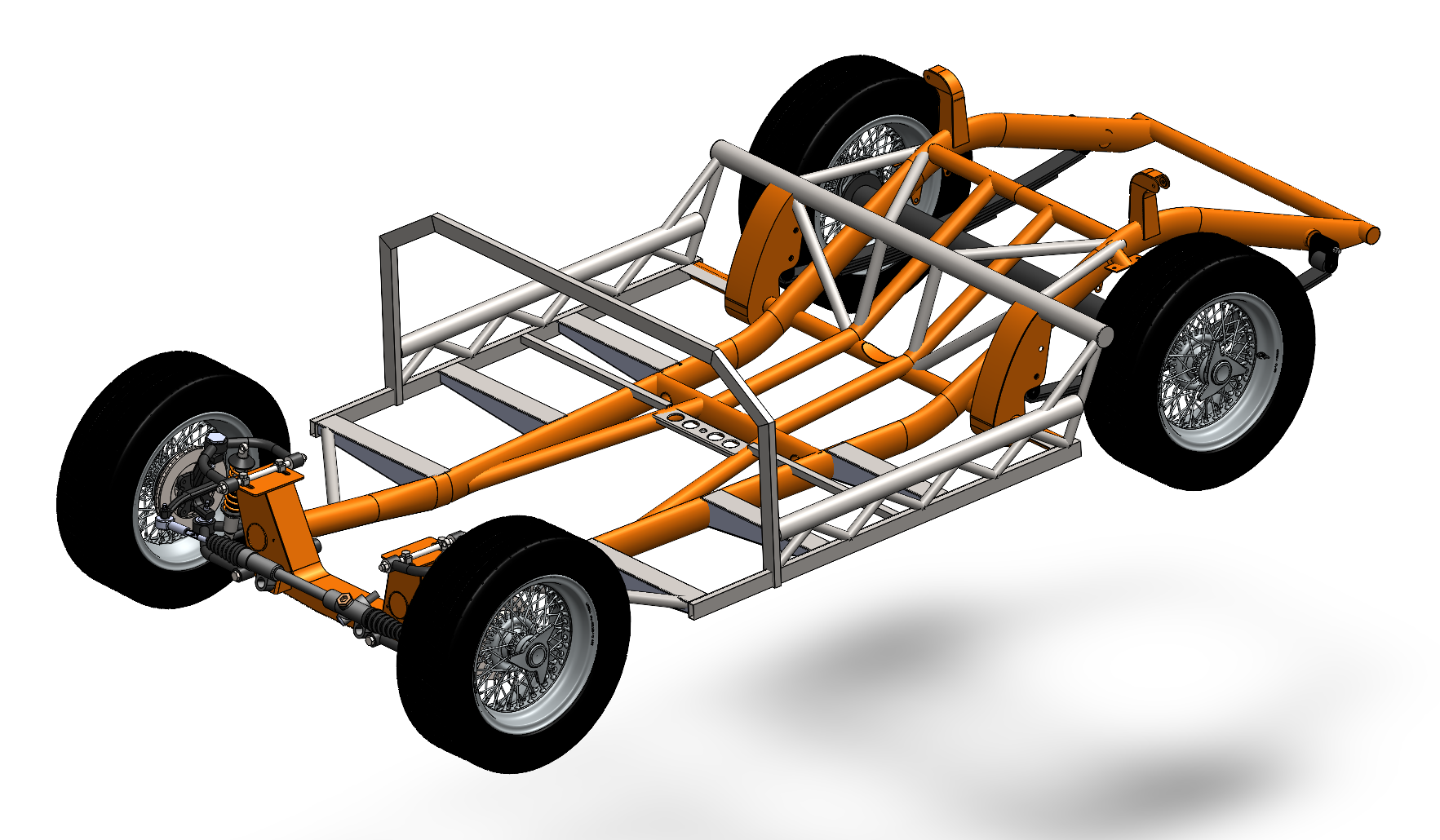

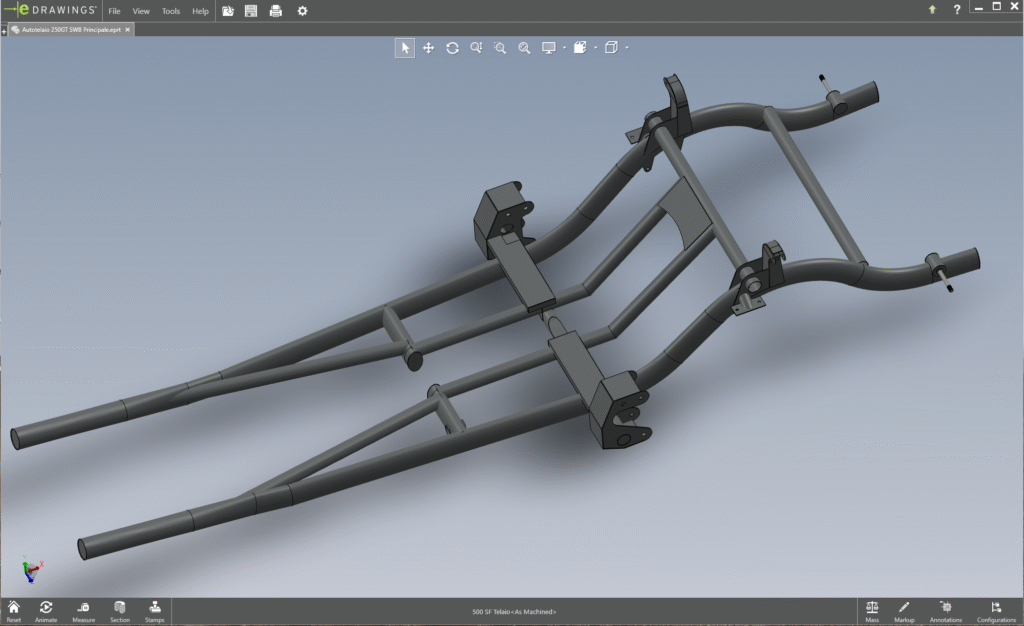

Telaio (Chassis Frame)

The telaio is a welded steel ladder or semi-oval tube frame. On the 250GT California SWB, the wheelbase measures 2400 mm. The chassis carries the engine, suspension, driveline, and provides the welded mounting points for the substructure. At the rear, semi-elliptical leaf springs are used, while the front employs unequal-length wishbones with coil springs.

Scocca Portante (Steel Body Support Structure)

The scocca portante – literally “supporting shell” – is a framework of steel tubing, brackets, and traverse (crossmembers) welded to the chassis. Its functions are:

Structural Alignment: Defines openings for doors, bonnet (cofano), and boot (bauletto).

Mounting Surface: Provides rigid steel to which aluminum panels are riveted or clamped.

Load Distribution: Helps distribute torsional and impact forces without stressing the thin aluminum skin.

Carrozzeria in Alluminio (Aluminum Bodywork)

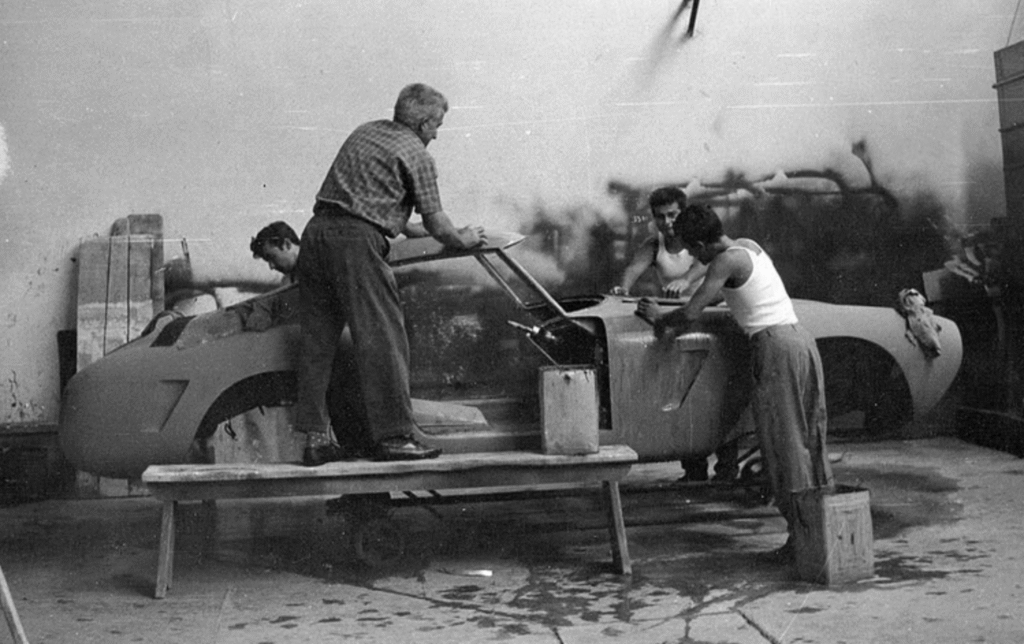

The outer beauty of the California is shaped in hand-beaten aluminum panels (lamiere di alluminio battute a mano). These were formed over wooden bucks (dime di legno) to capture the car’s flowing curves. Once shaped, the panels were carefully fitted to the support structure and attached by mechanical fasteners. Restorers often note small details such as lead-loading (piombatura) around seams, evidence of period finishing techniques.

Why Aluminum and Steel Are Not Welded Together

Although it may seem logical to weld aluminum panels directly to the steel frame, there are several reasons this was never done:

Metallurgical Differences: Aluminum melts at ~660 °C, steel at ~1500 °C, making direct welding impractical with period methods.

Differential Expansion: Aluminum expands nearly twice as much as steel when heated, which would cause welded joints to crack.

Galvanic Corrosion: Direct contact accelerates corrosion of aluminum in the presence of moisture. Coachbuilders used felt pads, sealants, or washers to separate the metals.

Coachbuilding Practice: Riveting allowed panels to be removed and refitted during the shaping process, essential for hand-built Ferraris.

Authentic Italian Terminology

Telaio → chassis frame

Scocca portante → steel body support structure

Traversa → crossmember

Carrozzeria → overall bodywork

Lamiere di alluminio → aluminum panels

Dime di legno → wooden bucks

Historical Context

Ferraris of this period were not monocoques. Instead, they relied on a three-part system: telaio (mechanical strength), scocca portante (body support), and carrozzeria in alluminio (lightweight sculpted form). This separation of these features balanced lightness, reparability, and racing durability. Restorers today must often rebuild the steel substructure first, since the aluminum bodywork only fits as accurately as the structure beneath it.