Hand Made Perfection at 1:1 Scale

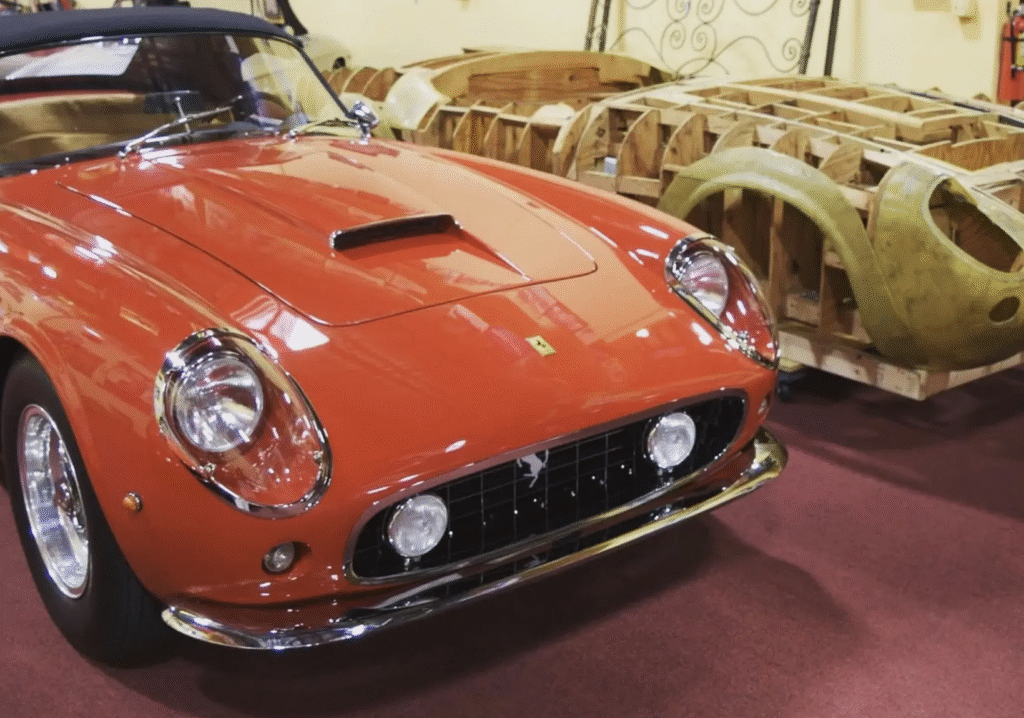

I recently acquired this California 250GT SWB wood buck used in the creation of body panels for a private collector. Believed to have been made in the late 1980’s, this wooden buck used for metal shaping is a historic restoration tool. A rare find with direct ties to the legendary 250 California Spyder.

Full Scale Accuracy For 1/4 Scale Model

This highly detailed and accurate buck played a vital role in shaping the alloy bodywork of many notable California’s that were damaged during racing, rebodied, or restored due to the ravages of time. Each contour, arch, and subtle surface transition was recorded in timber and then translated into hand-formed aluminum. For restorers, a buck like this is not just a reference but the foundation for recreating lines that define one of the most elegant sports cars of the twentieth century.

One of the greatest advantages of working from a full scale wood buck is dimensional accuracy. Every curve of the original design is preserved at life size, meaning the sweep of a fender, the tumblehome of a door, or the crown of a hood can be measured directly. When this buck is digitally scanned, the resulting 3D dataset provides a complete reference of the car’s true proportions and subtle surfaces without the distortion that comes from relying on photographs or drawings alone.

Once captured, the scan can be mathematically reduced to 1/4 scale while keeping all the original geometry intact. This ensures that the 1/4 scale model is not a simplified representation, but a precise miniature where every radius, break line, and surface flow is consistent with the real car. Builders can then create tooling, molds, or even 3D printed masters for a scale model that is faithful down to the smallest detail. This workflow eliminates guesswork and produces a result that is far more authentic than attempting to scale from blueprints or dimensions alone.

Why This Method Stands Apart

Traditional scale modeling often relies on measurements taken from published drawings, photographs, or second-hand dimensions. These sources can introduce errors in perspective, proportion, or scaling. By contrast, using a full scale buck means the baseline data is tied directly to a physical object that once guided real aluminum bodywork. This not only preserves authenticity but also captures the subtle artistry of Italian coachbuilding — features that are notoriously hard to recreate from two-dimensional references.

For collectors, restorers, and model makers, this method delivers the best of both worlds: the craftsmanship of the past and the precision of modern digital tools. The resulting 1/4 scale model becomes more than a display piece. It is a faithful study of the original car’s form, an educational tool, and a bridge between restoration practice and heritage preservation.

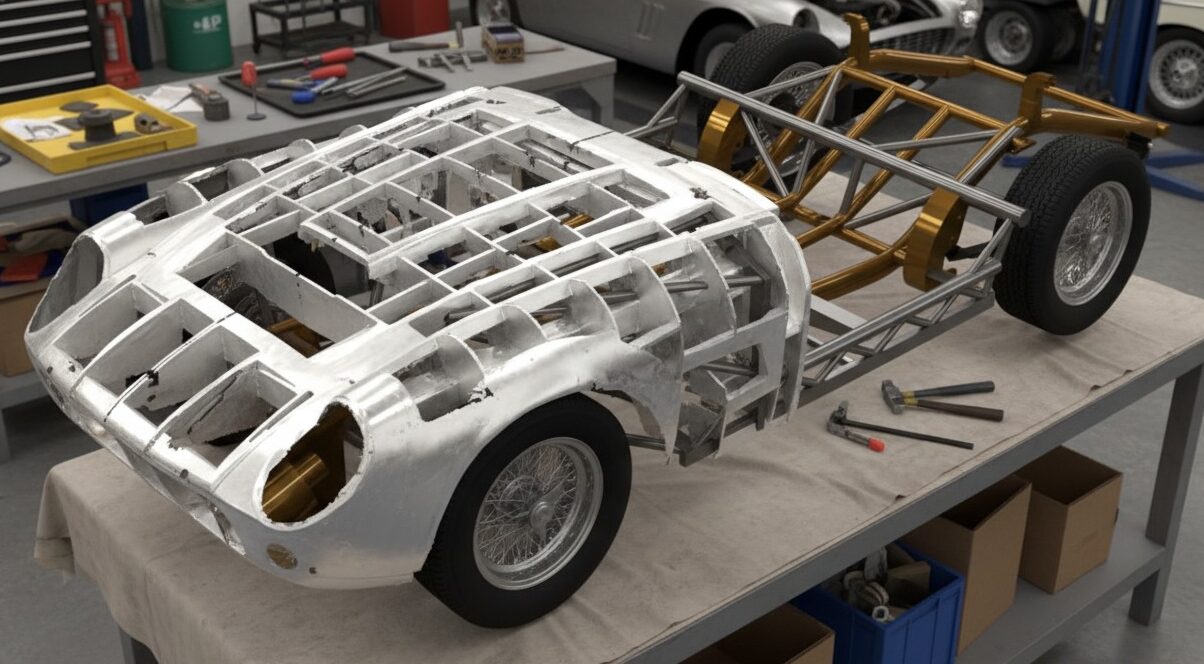

In traditional car restoration and metal shaping, a wood buck is a full-scale wooden form that represents the outer shape of a vehicle’s bodywork. Artisans use the buck as a physical guide, hammering and wheeling flat aluminum or steel sheets until they perfectly match the flowing curves of the design. This method predates digital tooling and remains essential in the world of coachbuilt classics because it allows precise, repeatable shaping of compound curves without the need for expensive dies.

Italian carrozzerie (coachbuilders) had their own words for these tools. A buck was often called a dima di legno (wooden template) or simply forma (form), while the process of hand-shaping over it was known as battilastra (literally, sheet-metal beating). The craftsmen, called battilastra or carrozzieri, would work sheet aluminum with hammers, mallets, and the English wheel, using the wooden form as a three-dimensional reference. Each panel was tested, adjusted, and then hand-fitted until the flowing Italian body lines were achieved.

On the 250 GT series California Spiders, SWB Berlinettas, and the legendary GTO—this technique was fundamental. Bodies were created by coachbuilders like Scaglietti, Pininfarina, and Touring, each employing their own bucks to translate a designer’s sketch into aluminum reality. Because many of these cars were built in tiny numbers, often fewer than a hundred units, expensive industrial stamping dies were impractical. Instead, wooden bucks made it possible to hand-produce lightweight alloy panels with consistency while still leaving room for subtle variations from car to car.

Historically, the use of dime (templates) and forme meant that the same buck could serve multiple projects: a competition body with flared arches, a road version with subtler curves, or even evolutionary updates during a model’s production run. For example, the 250 GT SWB’s shorter wheelbase demanded new bucks compared with the earlier long-wheelbase “Tour de France” Berlinetta, ensuring that proportions and aerodynamics were preserved in the new chassis format.

In restoration today, recreating missing or damaged panels for a 250 GT still begins with either an original buck (if it survives) or the painstaking recreation of one from drawings, photos, or 3D scans. Once built, the wooden form allows modern craftsmen to repeat the same age-old techniques—shrinking, stretching, and wheeling aluminum until it flows over the curves of the buck, just as Italian artisans did in Modena during the 1950s and ’60s.

This blend of wood and alloy represents the soul of coach built automobiles. Without dime di legno and the hands of skilled battilastra, the graceful silhouettes of the 250 GT would never have emerged. Even today, those bucks are a meeting point of art and engineering that continues to fuel our dreams.